Using microwave energy in a chemical reactor

Scientists are working on a chemical reactor equipped with a smart semiconductive source of microwave power for the precise control of the nano-fertiliser synthesis process.

“The use of microwave heating allows us to achieve increased efficiency and improved reproducibility of reaction conditions in comparison with convective heating,” says Przemysław Korpas, DSc, from the Faculty of Electronics and Information Technologies at WUT. “This way we can maintain a narrow regime of the set temperature and avoid local overheating. This is an important feature because in the case of nano-fertiliser synthesis even slight changes in the temperature may lead to modifications in the structure and morphology of obtained nanostructures, and consequently, in their potential nutritional properties and the level of absorption by the plants,” he explains.

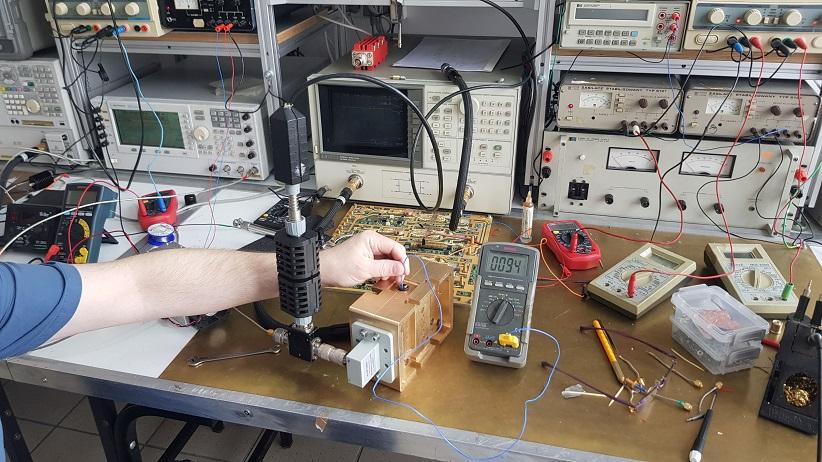

Research work required designing a reactor and a microwave source that will excite the reactor. At this stage, Dr Korpas’s team was supported by the ideas of Professor Wojciech Gwarek, a retired employee of the Warsaw University of Technology. Based on the proposed structure, researchers will be able to conduct simulations and then construct a proper reactor.

“One of the basic functions of a reactor is to replace electromagnetic waves with thermal energy emitted in reacting substances in a controlled way,” says Dr Korpas. “In a way, such a reactor may be compared to a home microwave oven, although there are obviously a lot of differences. We aim to ensure a possibly even heating level so that the heated substance keeps the set temperature. It is not easy to achieve because a reactor is a resonating structure that by nature is characterised by unequal distribution of the electromagnetic field. Another difficulty is the necessity to conduct a dynamic control of frequency and excitation power,” he explains.

In contrast to solutions known from the literature, which use a multimode resonant cavity as an area of interaction between microwaves and the heated substance, the innovative WUT project utilises a one-mode cavity with a special structure, in which the distribution of stimulated electromagnetic field will better meet the requirements of the nano-fertiliser synthesis reaction. Another novelty is the construction of the power source with an applicator for the ISM 5.8 GHz band, whereas a typical range for microwave heating devices is ISM 2.45 GHz. A shorter wavelength, nearer the planned dimensions (diameter) of the reactive vessel, will allow us to work with lower power levels and control the course of reaction more effectively.

“At the start of our work, we were thinking of what length and depth the reactor cavity should have, among other things,” says Dr Korpas. “We also spent a lot of time selecting the parameters in the electromagnetic simulator. We checked electromagnetic properties of a range of chemical substances as well,” he says.

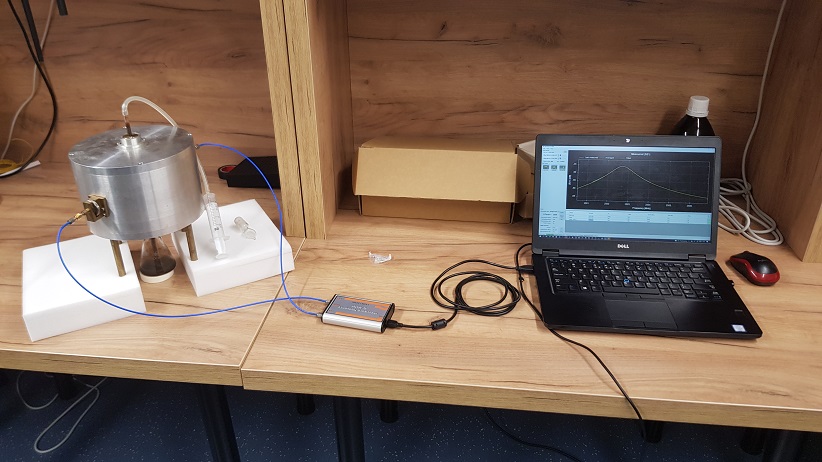

Another issue on which the researchers worked was the measurement of the temperature of the substance placed in the reactor.

“We selected thermal imaging sensors, which check the temperature of the test tube wall through the holes in the cavity,” explains Dr Korpas. “It is a compromise as traditional measurements inside the reactive vessel with an immersed probe is problematic. The issues include problems with sealing the vessel, risk of contamination of reactive substances, and unfavourable interactions of the strong electromagnetic field with a sensor. One should bear in mind, however, that contactless temperature measurement using thermal imaging sensors involves many technical difficulties such as ensuring that the mentioned holes allow the sensor to measure the temperature undisturbed, and at the same time, microwaves do not escape through them out of the reactor,” he says.

Currently, researchers are trying to patent the device.

_

Project “Chemical reactor vessel using intelligent microwave source” is funded by the BEYOND POB grant under the Excellence Initiative – Research University programme implemented at WUT.

Research team:

Przemysław Korpas, DSc; Professor Krzysztof Jankowski, PhD, DSc; Wojciech Wojtasiak, PhD, DSc, Associate Professor; Magdalena Borowska, DSc; Daniel Gryglewski, DSc; Sebastian Kozłowski, DSc; Dariusz Kołodziej, MSc; Adrian Kruczak, BSc.