Ultrasonic atomization of functional materials

More (materials under research) for less (money) – that is an achievement of the researchers at the Faculty of Material Engineering thanks to an innovative approach to the atomization of functional materials. Their research is conducted within the Material Technologies-1 research grant.

Additive technologies, which involve creating 3-D objects from thin layers of the material placed one on top of another, based on a digital file, are revolutionising the manufacturing sector. That especially applies to the manufacturing of metal elements with additional functionality, complex geometry, both in prototyping and small-scale production. Additive technologies are waste-free, as they reduce the use of materials and have an impact on the reduction of fuel consumption. Literally and metaphorically speaking, a large scale of processes generates high costs, negatively affecting the number of materials that could be potentially researched.

“Industrial atomizers require a huge amount of material, for instance, a kilo,” says Rafał Wróblewski, DSc at the Faculty of Material Engineering. “When we are working on a new alloy, we need to test it to check if it meets our expectations. The cost of one kilo of different elements to be used to produce a sample of the new alloy and its atomization is enormous. The proposed method facilitates taking a few or a dozen grams of those elements, creating an alloy, atomizing, and testing as little material as a pinch, half a teaspoon, a few cubic millimetres, or one cubic centimetre, for instance. The method allows us to accelerate the search for innovative alloys for additive manufacturing,” he explains.

Discovering the unknown

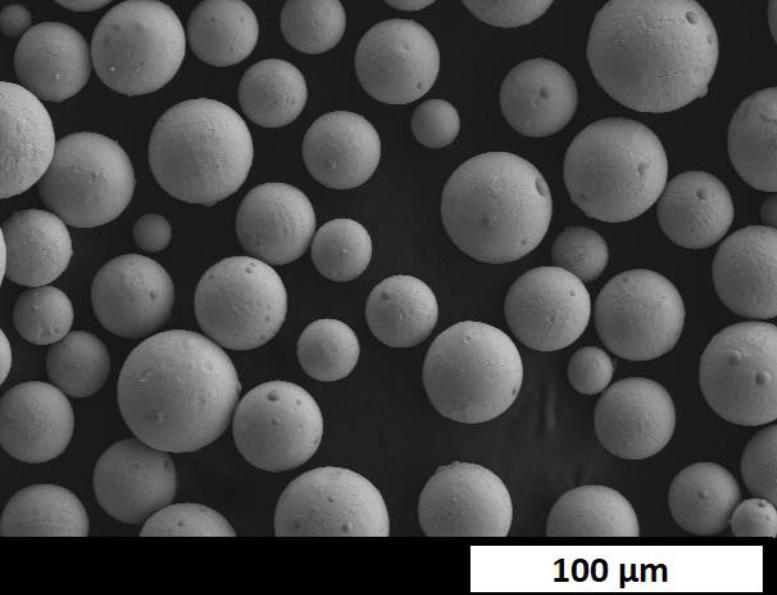

Atomization is the process of spraying a liquid into tiny droplets. One of its types is called ultrasonic atomization, which so far has been one of the most under-researched methods for creating powders from melted metals.

“Huge industrial devices blow liquid metal with gas or let it through a plasma furnace, as a result of which droplets are formed,” says Dr Wróblewski. “As soon as the droplets solidify into powder particles, they are collected. In our method, an ultrasonic sonotrode is utilised as a cool melting pot. The material is melted inductively or with an electric arc and atomized with vibrations,” he explains.

However, that is not the clou of the issue. The method utilising a sonotrode has been known before, but it has its limitations because of low resistance to high temperatures and high fatigue in the materials used for making sonotrodes.

“A sonotrode is an active element of the device which can vibrate with a frequency of 20,000 times per second, moving up and down,” says Dr Wróblewski. “Although the amplitude of this movement is not high, for example, 30 micrometres, this frequency can make the material “fatigued” and crack. The choice of the material for the sonotrode plays an important part in the atomization method. Perhaps our technique is not new, but our approach and the fact that we produce a wide range of materials, not only those with low fusibility, is innovative,” he emphasizes.

Prospects

Researchers at WUT have contacted several foreign centres interested in the atomization of unusual substances (including Ames Laboratory, which is part of the State University of Iowa, part of the Department of Energy of the USA, and one of the world leaders in testing ready devices capable of cooling by using the magnetocaloric effect).

„We have received gadolinium, which is a functional material, from Ames Lab,” says Dr Wróblewski. „To be specific, it is about a magnetocaloric phenomenon, which is a conversion of thermal energy because of magnetic field operations. Not only are we going to atomize gadolinium for Ames Lab but also to print ready elements for the testing device, and in the future perhaps for magnetic refrigerators,” he specifies.

The project "The Construction and Validation of Laboratory Station for Ultrasonic Atomization of Functional Materials for 3D Printing” is implemented as part of the competition for the Technologie Materiałowe-1 research grants.

Research team

Rafał Wróblewski, DSc; Bartosz Michalski, DSc; Jan Wróbel, DSc; Łukasz Żrodowski, BSc; Bartosz Morończyk, MSc.

Source of information: materials sent by Rafał Wróblewski, DSc.