In search of new methods of creating composites

One of the biggest defects of silicon carbide, which is a high-toughness material utilised in the machine tool industry, among other things, is its low fracture toughness. Most frequently, composites with silicon carbide matrix are produced to solve this problem. Unfortunately, most materials utilised as strengthening (composites) and increasing fracture toughness simultaneously negatively affect other properties of silicon carbide, including its toughness and maximum temperature of material work. The work on finding an ideal solution to this problem is continuing.

New possibilities of producing composites appeared with the development of nanomaterials with a two-dimensional structure, including graphene. However, utilising graphene to increase the silicon carbide toughness did not prove to be an ideal solution. This is mainly due to the difficulty in obtaining a high interphase boundary between silicon carbide and graphene, as well as the lack of gaps and microfractures, among others.

Innovative materials

Currently, MXene phases are the latest and most dynamically developing group of nanomaterials. They are obtained from MAX phases (M is a transition metal; A is a metal from group 13 or 12; X is nitrogen or carbon). Research shows that these phases have the potential to be utilised in medicine (e.g. in medical imaging), the construction of new-generation devices for storing energy, and biosensors.

The chemical composition and geometry similar to graphene imply that MXene phases can serve as strengthening in composites with silicon carbide matrix, too. The main issue with utilising MXene phases in this type of ceramic matrix is a high temperature required for proper density of the ceramic matrix, which considerably increases the temperature of decomposition of MXene phases. MXene phases decompose in the atmosphere rich in oxygen at a temperature above 300 degrees Celsius. Research shows that the mechanism of MXene phase oxidation can be altered by controlling the oxygen content and the humidity of the oxidising atmosphere, as well as by limiting the temperature and time of consolidation.

Jarosław Woźniak, D.Sc. from the Faculty of Material Engineering of the Warsaw University of Technology, says “Our research aims to obtain a homogenous interface without pores and discontinuities, and, at the same time, to eliminate one of the crucial defects of composites strengthened with graphene.”

First results

Based on the first research results, its authors have published a paper describing the findings. As far as the WUT research team knows, this is the first description of creating carbon structures in silicon carbide matrix as a result of MXene phase oxidation in the process of composite sintering.

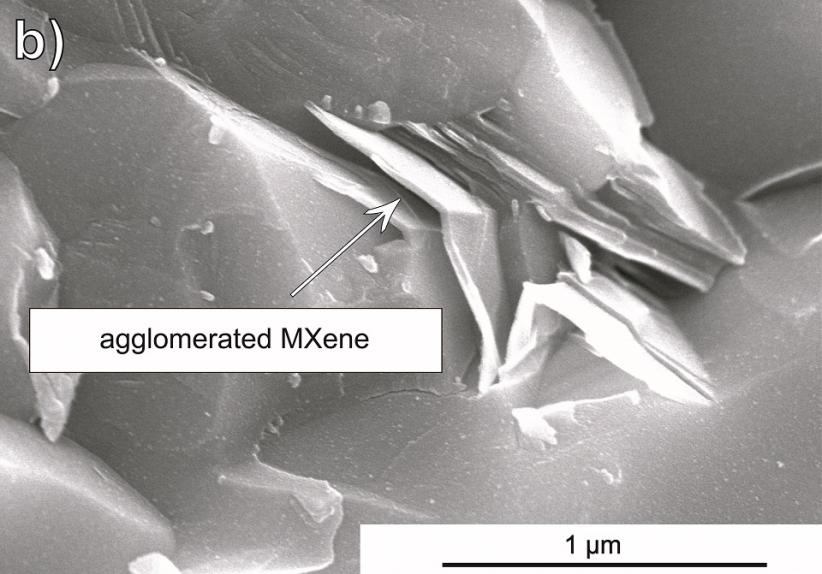

Jarosław Woźniak, D.Sc. says, “We have described attempts at creating composites in silicon carbide matrix with an addition of Ti3C2 phase using the Spark Plasma Sintering method and the results of research on its effect on the microstructure and mechanical properties of sinters.” He adds, “We have also analysed the structure of composites after sintering which allowed us to describe the mechanisms responsible for creating carbon structures as a result of MXene phase decomposition.”

During the conducted experiments it turned out that the addition of 2D-Ti3C2 phase had an impact on the mechanical properties of silicon carbide. The thorough analysis of the produced composites has enabled the researchers to specify the mechanism behind this phenomenon.

Woźniak explains, “During sintering, thermal decomposition of MXene phases occurs which results in creating defective graphite structures. It is possible thanks to combining a few factors: innovative sintering technology, proper sintering activators used and precisely adapted sintering conditions. The abovementioned factors lead to creating an atmosphere in the space between the particles of powders which is rich in compounds possibly responsible for MXene oxidation, which in turn results in creating defective carbon structures. Similar to graphene-strengthened composites, the presence of these structures hinders the grain growth and produces higher toughness of the material.”

Plans for future

The planned future work includes utilising the mechanism of MXene phase oxidation described above to devise technology for the production of ceramic composites strengthened with titanium carbides with a two-dimensional structure.

Project "Mechanisms of graphite-like structures formation due to oxidation of MXene phase during sintering by the SPS method in silicon carbide matrix composites" is funded under research grant Technologie Materiałowe-1.

Research team:

Jarosław Woźniak, D.Sc.; Mateusz Petrus, D.Sc.; Tomasz Cygan, M.Sc.; Andrzej Olszyna, Prof. Ph.D., D.Sc.

Source: materials provided by Jarosław Woźniak, D.Sc.